Project Description

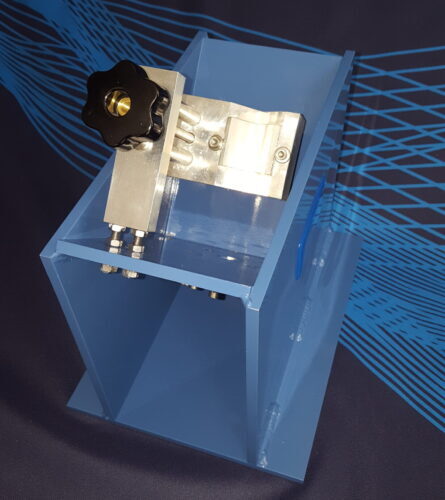

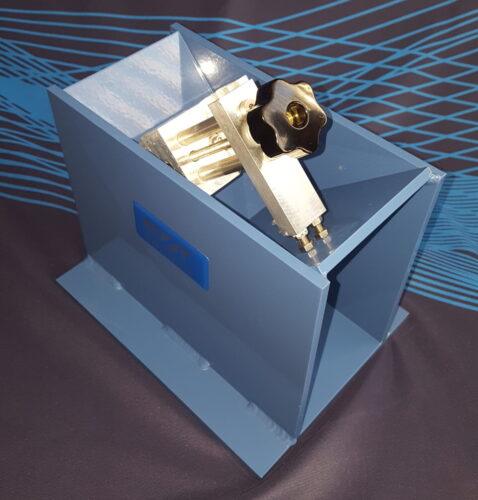

The Ultrasonic Bolt Inspection System is a mechanical fixture for manual immersion ultrasonic inspection of bolts for cracks in the thread, shank, or head-to-shank fillet. Its primary application is the nondestructive inspection of aircraft wheel tie bolts. It is also used for testing of automotive parts and other cylindrical components for voids, inclusions, and weld integrity.

Main features:

• V-shaped tank for holding ultrasonic coupling fluid.

• Height-adjustable V-block for precise positioning of the bolt relative to the transducer.

• Exchangeable guides for holding bolts and other cylindrical parts.

• Durable aluminum and plastic construction, non-corroding.

• Selectable ultrasonic transducers for inspection of thread and shank areas.

• Detection of cracks of less than 0.16” (4mm) in length and 5% of shank diameter in depth.

• No cleaning of threads or demagnetizing of bolts is required.

• Fast inspection, less than 6 seconds per bolt.