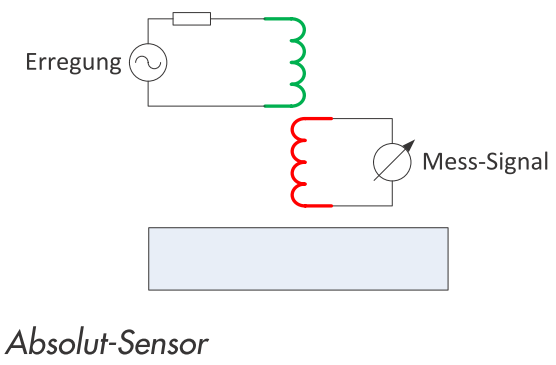

The term “absolute probe” is derived from the fact that the absolute value of the voltage induced in the test coil is measured. The signal of a defect or of a change in the characteristics in the body of the product to be tested is superimposed on the signal of a defect-free product or an empty coil. As such, the test signal is not just influenced by defects, but also by the characteristics of the material of the product to be tested and conditions in the environment. For example, should the probe become warm during operation, its electrical resistance changes and the absolute value of the induced voltage begins to drift. This is the big disadvantage of these probe systems. To suppress disruptive influences such as these or similar, often an additional compensation coil is interposed. It must be arranged in such a way that there can be no interactions with the product to be tested, but so that influences from the environment are effectively suppressed.